Description

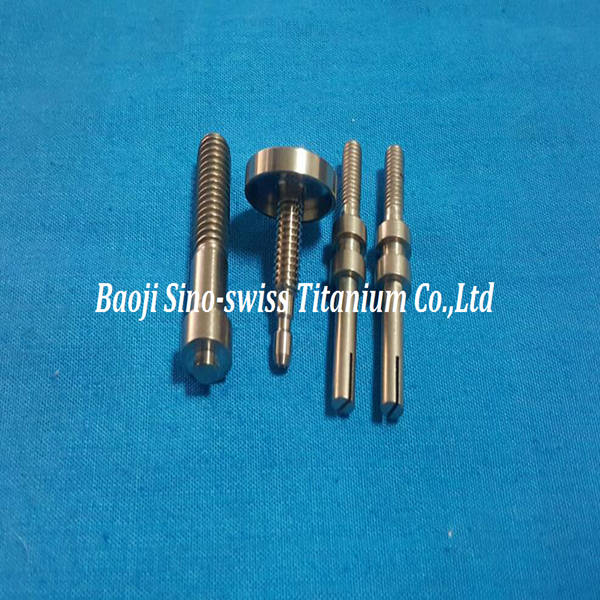

ASTM B381 Titanium Pipe Flanges are highly recommended to use in aerospace industry. Manifold Pipe Solution Inc. is custom design manufacturers of Titanium Grade 2 And Grade 5 Flange, Titanium Slip On Flanges, Titanium Socket Weld Flanges, Titanium Weld Neck Flanges as per the given drawing.

With requirements in both metric and U.S. We Manufacture Titanium Flange Material with rating class of 150#, 300#, 400#, 600#, 900# and 1500# in sizes NPS 1/2 to 24. For 2500# in sizes from NPS 1/2 to NPS 12 Titanium Header Flanges, All ANSI/ ASME B16.5 Titanium Blind Flanges are manufacturerd as per standard which include ANSI/ ASME (USA)/ ASA, PN/ DIN (European), BS10 (British/ Australian) and JIS/ KS (Japanese/ Korean). Buy directly from Titanium Flange Manufacturers

No other is Titanium Lap Joint Flange manufacturers can beat our price in Middle East because we have bulk stock of Titanium RTJ Flanges, Titanium Blind Flanges and Titanium Socket weld Flanges, Check our Uns R50400 Ansi Flange Price List

We have our own manufacturing plant to produce various sizes ASME SB381 Titanium Exhaust Flange & export to more than 60 countries like Singapore, France, UK, Japan, Germany, Australia, USA, Oman, Egypt, UK, Italy, China, UAE, Malaysia, Canada, Turkey, Sweden, Israel, Russia, Poland Qatar, Dubai, Saudi Arabia & South Korea.

| Specifications | Titanium Flanges |

|---|---|

| Titanium Flanges Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flanges. |

| ASME B16.5 Titanium Flange size range | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

| Titanium Flange Standard DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| Titanium Flange Standard ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Titanium Flange Standard UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Titanium Flange Standard EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Titanium Flange Standard JIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| Main Types | Forged / Threaded / Screwed / Plate |

| Flange supporting material | Gasket, Ring Joint, Flange Bolts |

| Most common types of Titanium Flanges |

|

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, , Groove |

| Titanium Pipe Flanges Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production technique |

|

| Special design | As per your drawingAS, ANSI, BS, DIN and JIS15 NB (1/2″) to 200 NB (8″) Equal and Reducing ConfigurationsTitanium Threaded Flange, Socketweld Flange, Slip-On Flange, Blind Flange, Weld Neck Flange |

| Specialized manufacturer of |

|

| Test | Hydrostatic testing machine, Direct-reading Spectrograph,UI trasonic flaw detector, X-ray detector, Magnetic particle detector |

| Equipment | Bending machine, Press machine, electric bevelling machine, Pushing Machine, Sand-blasting machine etc |

| Origin | West Europe /Indian / USA / Japan / Korean |

| Titanium Flanges Standard | ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc.

BS Flange, EN Flange, API 6A Flange, ANSI Flange, ASME Flange, DIN Flange, EN1092-1 Flange, UNI Flange, JIS/ KS Flange, BS4504 Flange, GB Flange, AWWA C207 Flange, GOST Flange, PSI Flange

|

| Key markets and industries for Titanium Flanges |

|

| Export to | Indonesia, Ireland, Ukraine, Singapore,Saudi Arabia,Canada, Peru, Dubai, Brazil, Iran, Korea, USA, India, Egypt, Thailand, Spain, Oman etc |

| Titanium Flanges Application |

|

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Click on below links for Titanium Flanges Standards

- JIS B2220 Flange

- MSS SP-44 Flange

- EN 1092-1 Flange

- SABS / SANS 1123 Flanges

- GOST 12820 80 Flanges

- API Flanges

- AWWA C207 Flanges

- ISO Flanges

- Australian Flanges

- Korean FLANGE

- BS 4504 Flanges

- BS 10 Flanges

15mm (1/2″) Titanium Flange Weight Chart

Standard | Class | Diameter | Bolt Circle Diameter | Number of Bolts | Bolt Size | Diameter of Bolt Hole |

|---|---|---|---|---|---|---|

AS4087 Flanges | PN14 Flanges | 95 | 67 | 4 | M12 | 14 |

AS 2129 Flange | Table C Flanges | 95 | 67 | 4 | 13 | 14 |

Table D Flanges | 95 | 67 | 4 | 13 | 14 | |

Table E Flanges | 95 | 67 | 4 | 13 | 14 | |

Table F Flanges | 95 | 67 | 4 | 13 | 14 | |

Table H Flanges | 114 | 83 | 4 | 16 | 17 | |

Table J Flanges | 114 | 83 | 4 | 16 | 17 | |

ANSI B16.5 Flanges | ANSI 150 Flanges | 89 | 60 | 4 | 13 | 16 |

ANSI 300 Flanges | 95 | 67 | 4 | 13 | 16 | |

ANSI 600 Flanges | 95 | 67 | 4 | 13 | 16 | |

ANSI 900 Flanges | 121 | 83 | 4 | 19 | 22 | |

ANSI 1500 Flanges | 121 | 83 | 4 | 19 | 22 | |

ISO 7005 (DIN) Flange | PN6 Flanges | 80 | 55 | 4 | M10 | 11 |

PN10 Flanges | 95 | 65 | 4 | M12 | 14 | |

PN16 Flanges | 95 | 65 | 4 | M12 | 14 | |

PN20 Flanges | 90 | 60.5 | 4 | M14 | 16 | |

PN25 Flanges | 95 | 65 | 4 | M12 | 14 | |

PN40 Flanges | 95 | 65 | 4 | M12 | 14 |

Click on below links for Titanium Flanges dimensions

- 150 LB Flange Dimensions

- 300 LB Flange Dimensions

- 600 LB Flange Dimensions

- 900 LB Flange Dimensions

- 1500 LB Flange Dimensions

- 2500 LB Flange Dimensions

- DIN 2527 Flanges

- DIN 2573 Flanges

- DIN 2576 Flanges

- DIN 2632 Flanges

- DIN 2633 Flanges

- DIN 2635 Flanges

- DIN 2642 Flanges

- ANSI B16.47 Flange

| AMERICAN SOCIETY OF MECHANICAL ENGINEERS (ASME) |

|

|---|